Calculation of Carding:

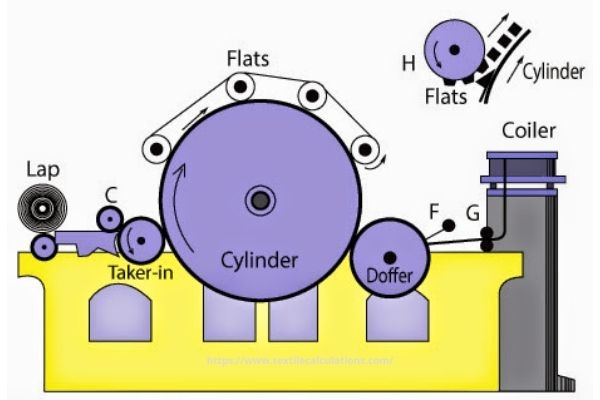

Carding is a mechanical process that breaks up, cleans, and intermixes fibers to produce a continuous web or sliver suitable for subsequent processing. Carding is one of the most important operations in the spinning process. It is called the heart of spinning. In this article, I have given various problems and solutions to carding. Before reading this article you should follow the formulas of carding operation.

Important Calculation of Carding:

Problem-1:

Calculate the cleaning efficiency of carding from the following data:

Trash in lap = 6.5 lbs

Trash in sliver = 1.5 lbs

Solution:

………………………………………………..Trash in lap – Trash in sliver

Cleaning efficiency of carding = ……………………………………………… X 100

……………………………………………………………Trash in lap

…..6.5 -1.5

= …………… X 100

………6.5

= 76.9%

= 77% (Ans).

Problem-2:

In a carding m/c D.C.P is 20 & draft constant is 2220. Find the draft of the m/c.

Solution:

We know,

………………..Draft constant

Draft = …………..……………………

……………Draft change pinion

…..2220

= ………..

……20

= 111. (Ans.)

Problem-3:

Find the required D.C.P from the following information-

Present D.C.P = 21 T

Present Hank = 14 Reqd Hank = 18.

Solution:

We know,

…………………………………………………..Present hank

Required D.C.P = Present D.C.P x ……………………….

…………………………………………………Required Hank

…………0.18

= 58 x ……….

…………0.16

= 65 T (ANS)

Problem-4:

Calculate the production/hr in kg of 10 carding m/cs from the following information –

Doffer r.p.m = 45,

Doffer dia = 27 inch,

Hank of sliver = 0.15s Ne,

Waste extraction = 4% &

Efficiency = 90%.

Solution:

…………………………….π x 45 x 27 x 60 x 90 x (100 – 4)

Production / hr = …………………………………………….……….. lb

…………………………………840 x 36 x 100 x 100 x 0.15

= 43.60 lbs.

= 19.78 kg. [1 kg = 2.204 lbs]

Production/hr of 10 carding m/c = 19.78 x 10

= 197.8 kg. (Ans.)

Problem-5:

Feed roller dia = 2.25 inch, Feed roller r.p.m = 4, Doffer dia = 27 inch, Doffer r.p.m = 30, Lap wt = 14 os/yd, Carding eff. = 90%. Find the prodn/hr in lbs.

Solution:

……………………….1 yd x 1 lb

Lap hank = …………………………….

………………….840 yds x (14/16)

= 1.36 x 10-3

……………Surface speed of delivery roller

Draft = …………………………………………………

……………..Surface speed of feed roller

…..π x 27 x 30

= …………………

….π x 2.25 x 4

= 90

We know,

…………..delivery hank

Draft = …………………….

…………….feed hank

Delivery hank = 90 x 1.36 x 10-3 = 0.1224.

We know,

………………………………π x D x N x 60 x 90

Production / hr = …………………………………… lb

………………………….840 x 36 x 0.1224 x 100

…..3.14 x 27 x 30 x 60 x 90

= …………………………………… lb

…..840 x 36 x 0.1224 x 100

= 37.11 lbs.(Ans.)

Problem-6:

The surface speed of the coiler wender rollers calculated & found to be 39.1 m/min. If the linear density of the sliver is 4 kilo Tex (4 kg/ km). What is the production per hr at 80% efficiency?

Solution:

Production = πDN x Efficiency

…………….80

= 39.1 x ……… m/min

……………100

…………….80 4

= 39.1 x ……… x ………… x 60 kg/hr

……………100 1000

= 7.50 kg / hr (Ans.)

Problem-7:

Here, doffer r.p.m = 1, Dia = 27 inch, sliver wt = 1 grain/ yds. Tension draft = 1. Find the production constant at 85% eff.

Solution:

…………………………………….πDN x 60 x eff .x sliver wt./grain x tension draft

Production constant = …………………………………………………….…………………………

………………………………………………………..36 x 100 x 7000

= 0.017 (ANS)

Problem-8:

Calculate the production in a card from the following details – Doffer r.p.m = 9.95, sliver wt 50 grains/yd, prodn const. 0.017, tension draft 1.03, efficiency 85%

Solution:

Production = Production constant x doffer r.p.m x T.D x sliver wt. gr/yd

= 0.017 x 9.95 x 1.03 x 50

= 8.71 lbs. (Ans.)

Problem-9:

Feed mtl wt. (lap wt) = 14 oz/yd, total draft of m/c = 105, doffer speed = 30, dia = 27 inch, eff. 85%. Calculate prodn in lb/hr.

Solution:

………………………..1 x 1

Lap hank = ……………………..

…………………..840 x 14/16

Feed hank = 1.36 x10-3

Draft hank = draft x feed hank

= 105 x 1.36 x10-3

= 0.1428

………………………….3.14 x 30 x 27 x 60 x 85

Production/hr = ………………………..…………….

………………………….840 x 36 x 0.1428 x 100

= 30.04 lbs (Ans.)

Problem-10:

Find the total prodn of a carding m/c for 1 hr with following details: doffer r.p.m = 10, dia = 27 inch, sliver hank = 0.15, eff. =90%.

Solution:

…………………………..π x D x N x eff .x 60

Production/hr = ………………..………………….

…………………………..lbs 36 x 840 x count

……3.14 x 27 x 10 x 60 x 90 x 1

= …………………………………………..

……….36 x 840 x 100 x 0.15

= 10.098 lbs (Ans.)

Problem-11:

Find the prodn calculation of carding m/c for 8 hrs with the help of following data: c. roller r.p.m = 80, dia = 4 inch, sliver hank =.14, eff. = 85%, tension draft =1.05

Solution:

………………………3.14 x 80 x 4 x 0.85 x 60 x 8

Production = ………………………………………………..

………………………………………….36

= 11393.536 yds/ 8 hrs

Production of Coiler Calender roller = 11393.536 x 1.05 yds/ 8 hrs.

= 11963.213 yds/ 8 hrs.

………………………………………………………………………..1

Production of carding machine = 11963.213 x ………………. lb/8 hrs

…………………………………………………………………3.14 x 840

= 101.72799 lbs/ 8 hrs. (Ans.)

Problem-12:

In a calculation of carding m/c it produces sliver wt. of 60 gr/yds when its DCP is 17. To produce sliver wt. of 70 gr/ yds then how many teeth of D.C.P should be used?

Solution:

……………………………….Present D.C.P. x Required wt of sliver

Required D.C.P. = …………………………………………………………………

………………………………………….Present wt. of sliver

………….90

= 17 x ……….

………….60

= 25.5

= 26 (ANS)

Problem-13:

The present produced sliver hank of a carding m/c is 0.16. Present D.C.P 18T. If reqd DCP is 22T, then calculate the sliver hank (required).

Solution:

……………………………………………………………………Present D.C.P.

Required sliver hank = Present sliver hank x ……………………………

…………………………………………………………………..Required D.C.P

…………….18

= 0.16 x ………

…………….22

= 0.130 (Ans.)

Author of this Article: Abdullah Nur Uddin Rony Textile Engineering College, Noakhali Facebook: Abdullah Rony

Very good post, that's help my works. Thanks.

Many culculation r tottally confusing me couse of not showing clearly r not in details

But i can solve all these calculation in simple way its my formulas only very simple nd clear

This comment has been removed by the author.