7 Steps of Apparel Analysis in the Garment Industry

Kazi Md. Rashedul Islam

B.Sc-in-Textile Engineering (DUET)

Author & Founder: TextileTrainer.com

Email: [email protected]

What is Apparel Analysis?

Apparel analysis is a systematic evaluation of the various aspects of garments and clothing items. For a merchandiser, apparel analysis is an important term. Generally, the apparel analysis process involves seven basic steps. The steps in the apparel analysis process vary depending on the individual conducting the analysis, the purpose of the analysis, and the methods employed. From a merchandising point of view, the apparel analysis process is performed to satisfy the needs and wants of consumers or buyers. Three different ways can be used to analyze clothing:

- Visual inspection: This method is simple and involves the least complicated procedure for inspecting and analyzing a garment. It is useful for evaluating the overall garment appearance and aesthetics, estimating fabric quality, identifying stitches and seam types, and also estimating the number of stitches per inch.

- Augmented visual inspection: This method involves a visual inspection supplemented by simple test procedures and measuring devices. This method provides far more detailed information than a mere visual assessment.

- Laboratory analysis with standard test methods: When it comes to analysis, this method gives the most scientific and reliable data that can be used again and again. These tests follow the rules set by the American Association for Textile Chemists and Colorists (AATCC), the American Society for Testing and Materials (ASTM), the British Standard (BS), and the International Standard Organization (ISO).

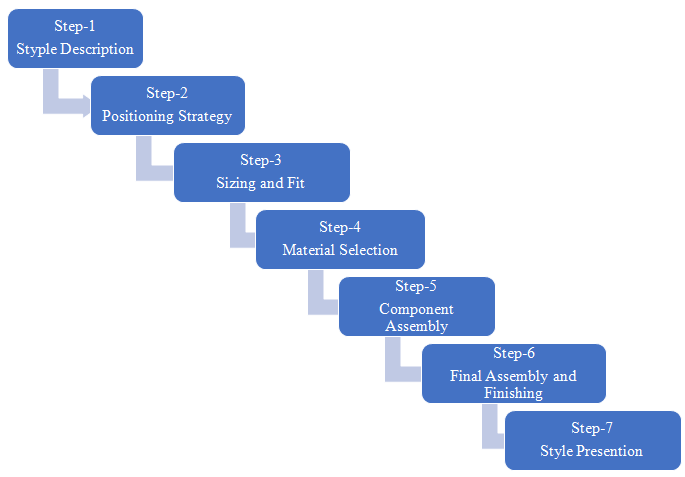

7 Steps of Apparel Analysis:

The simple steps involved in the apparel analysis process as given by Ruth and Grace are given below:

Step 1: Style Description

The first and most basic step in the clothing analysis method is to describe the style. As this process progresses, the merchandiser will create specific information about the garment’s style and share it with other departments so they can better understand it. This description contains the details like:

- Brand

- Style number.

- Merchandise group.

- Selling period.

- Body types and size ranges.

- Verbal description of the garment and fabric used.

- Detailed drawing of the front and back appearance of the garment.

- Special instructions related to the production and execution of the garment.

Step 2: Positioning strategy

In this step, the merchandiser categorizes the garment based on its application, usage, structural look, and silhouette. The garment will be rated on a five-point scale based on its group after inspection. The criteria used are provided below:

Here, the intrinsic cues represent the observable intrinsic qualities of a garment, such as the materials used, the assembly technique, the stylistic elements, fit, and finishing. The most prevalent extrinsic cues indicating quality and worth are advertising, visual merchandising techniques, pricing, brand, and the reputation of the producer or store. In contrast, extrinsic cues convey the image of the product. We can infer that the item is more functional if the merchandiser assigns a rating of 4 or 5, indicating its closeness to functionality. On the other hand, if the merchandiser assigns a rating of 4 or 5, close to aesthetic, it suggests that the item is more visually appealing.

Step 3: Sizing and fit

This section of the apparel analysis process analyses the size and fit details of the garment. The various details analyzed are given below:

- Size range

- Gender

- Body type

- Size indicator

- Fit level

- Silhouette and circumference

Step 4: Material Specifications

In this section, detailed information about various materials used in the garment is provided, along with samples or pictures to get a better understanding. The common specification details contain the following information, which is listed below:

- Number of materials used.

- Material list.

- Material name.

- Material description.

- Fiber and yarn details.

- Fabrication methods.

- Structural design

- Colours

- Finishes used

- Care information.

Step 5: Garment component assembly

The preliminary task of this portion is to break up the individual operations in the garment and identify the different parts of the garment. After identifying the parts of the garment, the simplest possible way of assembling the components will be detailed. The activities are given below:

- Identify and list the garment components.

- Materials of the components.

- Number of parts per component

- Operation breakdowns.

- Types of stitches and seams used.

- The number of parts to be assembled

- In-process pressing information

Step 6: Final assembly and finishing

It describes the steps involved in the garment’s final assembly, which entails sewing the assembled parts together to create the finished article. At this point in the production process, the merchandiser will provide advice on the operation sequence to follow. There will be stringent guidelines to adhere to in order to meet the required garment quality specifications. We present the information we developed at this stage of analysis:

- Total number of components and materials

- Final assembly operations

- Types of seams and stitches to be used.

- Finishing operations.

- Color matching procedures.

- Overall instructions and requirements.

Step 7: Style Presentation

The final section of the analysis outlines the packing and display details that are crucial for the final consumer presentation of the garment. This process covers the following aspects in detail:

- Labelling

- Accessories

- Packing method

- Hanger

- Accuracy of information

- Placement of the information

- Product appeal

The information obtained through this apparel analysis process will help the merchandiser develop the specification sheet, or “Tech Pack’. Small-scale industries, where they receive the sample garment directly, generally adopt this second method of developing technical specifications. Because they lacked a dedicated design department, the merchandiser will analyze the clothing, produce the technical data in black and white, and distribute it to all relevant department staff.

Conclusion:

The main object of the apparel analysis process is to ensure the development of high-quality garments. The apparel analysis process also helps to produce marketable products that meet buyer demands. So every merchandiser should know the apparel analysis process. Here, I tried my best to present an easy way of the apparel analysis process. Feel free to ask me any questions about this article via the comments box.

References:

- Belal, P. D. (2016). Understanding Textiles for a Merchandiser. Dhaka: L.B Graphics and Pringing.

- Corbman, B. P. (1987). Textile Fiber to Fabric. Singapore: McGraw Hill Book Co.

- Kadolph, S. J. (2006). Textiles. New Delhi: Pearson Education.

- Rathinamoorthy, R. S. (2018). Apparel Merchandising. Chennai: Woodhead Publishing India Pvt. Ltd.

Nice and informative post