Textile testing is a critical process that evaluates the quality, performance, and safety of fabrics, yarns, and fibers. The textile industry involves a wide range of processes from fiber production to garment manufacturing. To ensure that textile products meet quality, safety, and performance standards, various industrial testing methods are employed throughout production stages. These testing methods assess the physical, mechanical, chemical, and colorfastness properties of textiles, ensuring that materials are suitable for their intended applications. In this article, we will explore samples of commonly used industrial testing methods in the textile sector.

Sample of Industrial Testing Methods in Textile Industry

The following is a simplistic explanation of tests that are carried out. The standard tests are very detailed in how they should be conducted, and they include strict regimes to ensure that all tests are carried out in a controlled manner. Often, there are guidelines for the results to be acceptable for fabrics or products to meet the standard.

Abrasion Resistance:

Circular pieces of fabric are placed under rotating discs on a Martindale machine. The discs rub the fabric for a set number of cycles, and the effect on the surface of the fabric is recorded. Effects range from nothing to furriness to a hole.

Color Fastness:

Grey versus grey, white versus grey and blue versus blue scales are used for the assessment of changes in color of tested materials against a control sample.

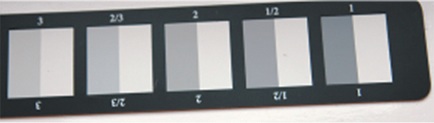

Greyscale:

Grey versus shades of grey are used to assess changes in color to fabric after a number of processes e.g. washing and perspiration, have been carried out.

Greyscale: one-half remains the same dark shade of grey and the other results in a gradual reduction in the shade of grey:

5 = both halves the same shade of dark grey; no change.

1 = dark shade grey against a light shade of grey means a significant color loss.

White versus shades of grey are used to assess the staining of fabric.

White starts with white v white moving to darker shades of grey:

5 = white against white which means all of the stain has been removed.

1 = white against dark grey meaning significant staining.

Both assessments use a scale that runs from one to five and consists of nine pairs of chips.

Blue Scale:

Blue scales are used for assessing changes in color to light. A scale that runs from one to eight is used. A constant blue is used on one-half, and the other results in a gradual reduction in the shade of blue. Eight means no color change has occurred and one means a significant color change has occurred.

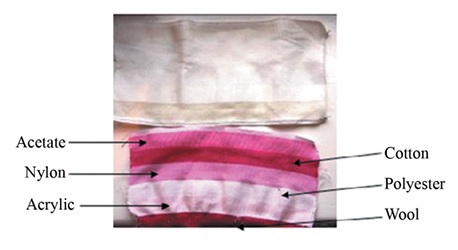

Color fastness also considers changes that entail colors bleeding into adjacent materials. For this assessment, multi-fiber strips are used:

The top fabric shows the multifiber strip in the greige state, and the bottom one shows where color has been absorbed. Note the degree of absorption according to the fiber content

(NB: The above picture shows fiber content of Multifiber DW fabric. Often manufacturers and retailers will use Multifiber LyoW™; this has replaced acetate with Lyocell as this is found more commonly in fabrics for apparel than acetate.)

Washing Fastness:

Uses a multi-fiber strip to check bleeding. It is placed into a washing machine with the fabric to be tested and run through a typical cycle. Any loss of color will be absorbed by the fiber strip due to the absorption property of the fiber. A fabric’s color loss is graded on a greyscale and it should show a color change similar to that which occurs after five commercial or home launderings at 40⁰c. Other areas considered in washing are shrinkage and deterioration of the fabric or product.

Light Fastness:

Fabric is placed into a xenon arc test chamber and subjected to light from bright to dim for a period of time. The samples are graded according to blue scales ranging from zero to eight. Similarly, testing a product’s resistance to ultraviolet light can be carried out using fluorescent UV lamps. The degradation of fabric is also considered when light testing.

Perspiration Fastness:

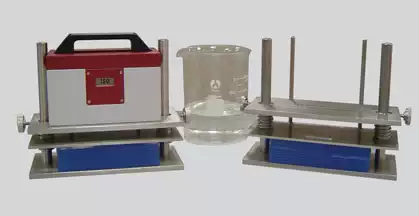

Fabric is saturated with a perspiration solution and placed in a perspirometer in an oven for six hours to simulate typical exposure. Color change and staining are compared to greyscale and color bleeding into the multi-fiber strip.

Crocking Fastness:

(rubbing) fabric sample is placed on a crock meter, and a white, 100% cotton fabric is rubbed across the sample ten times in wet and dry states. The white fabric is examined for staining. Staining can be compared on white scales that range from zero to five.

Crease Recovery:

Fabric is creased under a weight for a period of time. When is it released, it is placed in the clamp of the tester and left to open. After that, the angle of recovery is recorded.

Draping:

This test can be conducted in two ways.

- Test the stiffness of the fabric by pushing a strip of fabric forward until gravity causes the strip to bend a prescribed amount; the greater the pressure applied, the more stiff the fabric.

- Place a circular piece of fabric over a disc and create a shadow of the draped fabric on paper. The smaller the shadow the greater the draping property.

Flammability:

Fabric is mounted inside a stainless steel chamber with a glass front panel that enables observation. A flame spread with 0.1 second increments from ignition tries to ignite the fabric. The recorder will note the time and what happens to the fabric from nothing, burnt to ash or melted to a black residue.

Insulating:

This test is conducted by using a tog meter connected to a heat unit in a sealed chamber with a fan that maintains external temperatures. The tog meter has three temperature sensors; the first and second are attached to the heat unit either side of a prior known insulator, and the third one is above the fabric being tested. The fabric is placed under the lid between the second and third temperature sensors. Once the temperatures have stabilized, recordings are made of the temperature flow of the known insulator (between the first and second sensor). After that the temperature flow of the fabric being tested is recorded (between the second and third sensor). These results are compared to those of the known insulator.

Pilling:

Fabric samples are placed into a pilling chamber that is lined with an abrasive material. The chamber rotates, forcing the fabric against the abrasive material for approximately thirty minutes. Fabrics are observed for the small balls of fibers (pills) on the surface of the fabric. The Martindale machine can also be used for this test.

Snagging:

Fabric is placed over a rotating cylinder, and a mace dances across the fabric as it goes around, which clips fiber and yarn ends that may snag the fabric. The snagging is classed by protrusions, small yarn or fiber ends sticking out of the fabric and distortion of the warp or weft in woven fabrics or course or wale in knitted fabrics. The pilling device can also be used for this test.

Stiffness:

Calculates the bending height, flexural rigidity and bending modulus of fabrics.

Strength:

A strip of fabric is placed vertically between two clamps. The clamps move outwards to create tension in the fabric. This process continues until the fabric starts to tear. Results are recorded as the kilogram force required to burst the fabric or seam.

Tear:

A dot is placed in the centre 25mm from the top edge of a rectangular piece of fabric. The fabric is cut from the bottom edge towards the dot, but the cut ends 25mm from it. The fabric is placed into the jaws of the machine with one cut edge going towards the bottom jaw and the other one going towards the top jaw. The slack is taken up by the jaws moving apart, and they continue to move apart until the tear reaches the dot. Results are recorded as the kilogram force required to tear the fabric to the dot.

Seam Strength:

A seam is held in a frame over a waterproof membrane. Water pressure is applied from underneath, upwards towards the seam. This is done until the seam bursts. Results are recorded as the kilogram force required to burst the seam.

Water Resistance to Penetration:

This test can be conducted in a number of ways. Place fabric onto a small frame then water pressure from underneath is applied. The test ends once a droplet of water has penetrated the fabric. The kilogram force is recorded using a hydrostatic head machine.

Another method uses the Bundesman machine. It has a chamber with what looks like a shower head. Water cascades onto a product that has been placed on a frame or product such as a raincoat. The water pressure, time, and penetration of the product are recorded. Some companies apply a similar test using a wet room: people wear the products in the chamber and move around in the equivalent of torrential rain.

Moisture Vapour Transfer:

Water is poured into a turl dish and weighed. Fabric is sealed over the dish and left in an open space for twenty-four hours. The water is weighed again. Any loss of water means that it has evaporated through the fabric; an indication that the fabric is breathable.

Wind Resistance:

The fabric is placed on the bed of the machine and held down. A compressor in the machine tries to suck air through the fabric, and sensors measure the amount of air that passes through.

Simple Testing Methods

Whenever testing there should always be a control sample to which tested fabric can be compared. The control sample is a piece of the same fabric that is being tested; it is cut to an accurate size and kept in a brown envelope to prevent any discoloration from sunlight.

Washing: Two samples of each fabric are cut into 5cm x 5cm squares. One sample is washed at 40ºC, and the other is washed at 60ºC. If stain removal is a consideration, stains must be applied to the fabrics (e.g. oil, grease, blood, grass, dirt, make-up or food) and left to dry. When comparing the test sample to the control sample, observations should also include shrinkage, color fastness, fraying and stains.

Ironing: The temperatures at which creases are eliminated when dry or steam ironing is used. Also, checked is color fading and the melting of fibers. This test can be conducted after the washing test.

Crease Resistance: Either crumple a piece of fabric tightly in one’s hand for a few minutes and release the pressure, or fold the fabric and place the material under a heavy weight. Record what happens to the fabric when the pressure or weight is removed. Observations may include the speed at which the fabric opens, how deep the creases are and how much ironing is required to remove the creases.

Color Fastness to Light: This test is used only for soft furnishings. Place samples on a window that offers direct sunlight for part of the day. The control piece must be left in a brown envelope so no light reaches it. Ideally, the sample should be in the sunny spot for three months; but if this is not feasible the sample should be exposed for a minimum of four weeks. Observation of any color loss as compared to the control sample.

Durability: Cut a piece of fabric large enough to cover the top of a jar and secure it with an elastic band. Rub the surface of the fabric with a scourer, but make sure not to rub the fabric that touches the lip of the jar as this is more likely to result in a hole. Rub the surface for about thirty seconds. Observe the following: no effect, a furry surface, fiber deterioration or a hole in the fabric.

Keeping Warm or Cool: Wrap fabric around a conical flask and secure it with an elastic band. Pour boiling water into the flask and seal it with a rubber bung that contains a thermometer. Record the temperature. Leave the flask for thirty minutes and record the temperature again. The last part of the test may be repeated several times to increase accuracy. If the temperature remains about the same, the fabric holds heat and will keep the wearer warm. If the temperature drops, the fabric allows heat to dissipate and will keep the wearer cool.

Draping: Cut out a circle of fabric twice the size of a jam jar. Place the jar in center of a sheet of graph paper on a table. Place the fabric over the top of the jar before placing a light or lamp high above the center of the jar and turning it on. Trace the shadow cast on the paper. From there, work out the square meters – the smaller the area, the better the draping quality of the fabric.

Lightweight: This test can be conducted without an electronic scale. Cut out rectangles of the fabrics that are all the same size. Hold the rectangles parallel to the floor, drop them from a predetermined height, and time how long it takes each one to land on the ground. The longer it takes to get to the ground the lighter the fabric is.

Conclusion

Industrial testing methods play a vital role in maintaining the quality, safety, and performance of textile products. Besides, industrial textile testing provides essential data for manufacturers, regulators, and consumers. From physical and mechanical assessments to chemical and functional property tests, each method ensures that textiles meet both regulatory standards and customer expectations. As textile technology advances and consumer demands evolve, consistent and precise industrial testing will continue to be essential for sustaining product excellence in the textile industry.