Loop Length Control:

Loop length control is an important feature in modern knitting machines that allows for precise control over the length of each loop or stitch in the knitted fabric. This feature is particularly useful in producing fabrics with consistent texture, gauge, and density.

In a knitting machine, loop length control is achieved by controlling the movement of the knitting elements, such as the needles, sinkers, or sliders, that form the loops. The machine may use various sensors, actuators, or controllers to adjust the movement of these elements in response to changes in yarn tension, feed rate, or other parameters.

Loop length control is essential for producing high-quality knitted fabrics with consistent stitch size, shape, and tension. In some applications, such as the production of technical textiles or medical textiles, even minor variations in stitch size or tension can have significant impacts on the performance and durability of the final product.

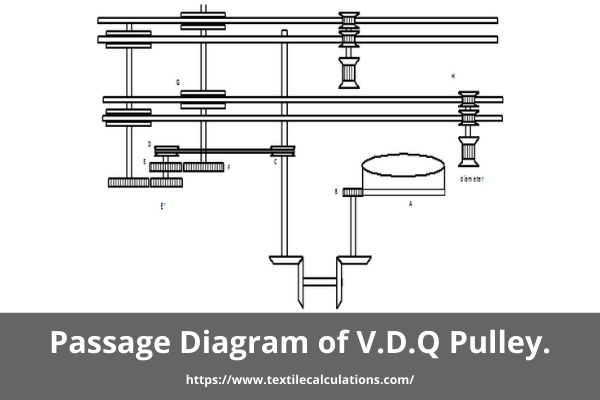

In a knitting machine, V.D.Q. Pulley is used to supplying the specific length of yarn. There are two or more adjustable pulleys which are known as V.D.Q. Pulley. By adjusting the V.D.Q. pulley we can control the speed of the accumulator which supply the required amount of yarn. V.D.Q. the pulley is very important to set up the correct loop length. The amount of yarn wound on the accumulator by one revolution of the cylinder is called the course length of fabric. In this article, we will discuss how to control loop length in a knitting machine.

A circular knitting machine produces a fabric with more than two knitting tools. The variation of yarn tension between different knitting tools causes different loop lengths of stitches during the knitting process. Here, a newly developed method is applied to control the loop length of stitches. In various tools based on the ideal shape of stitches and real angle of stitches direction while different loop length of stitches. Which causes stitches deformation and deviation those of angle. To measure the deviation of stitch direction against variation of tensions, an image processing technique applied to pictures of different fabrics with constant front light.

-

Pig: Passage Diagram of V.D.Q Pulley How to Control Loop Length in Knitting Machine

Course length= 1 × (A/B) × (C/D) × (E/F) × (G/H) × πd,

Where d is the diameter of the accumulator.

Course length =K × G

K = Constant = (A/B) × (C/D) × (E/F) × πd

K = Course length/ G

Course length =K X G

N × l = K × G

=>l = ( K× G) / n

= (K/n) × G

= MG (M=K/n Which is fixed for a specific cylinder)

Sometimes, for a specific loop length, the required V.D.Q pulley is needed more or less than the numbered V.D.Q pulley value. For this condition, we have to change the constant value ‘k’. To change the ‘k’ we have to change E,F,E’,F’ gear.