5-Wheel Take up Mechanism:

The process of withdrawing fabric from the weaving zone at a constant rate and then winding the woven cloth on the cloth roller with the continuous progress of weaving is called take-up motion. For doing this work two types of machines are used. One is the 5-wheel mechanism and another is a 7-wheel mechanism. A 5-wheel take-up mechanism is used in the case of jute weaving. In this article, I will discuss a calculation of the 5-wheel take-up mechanism.

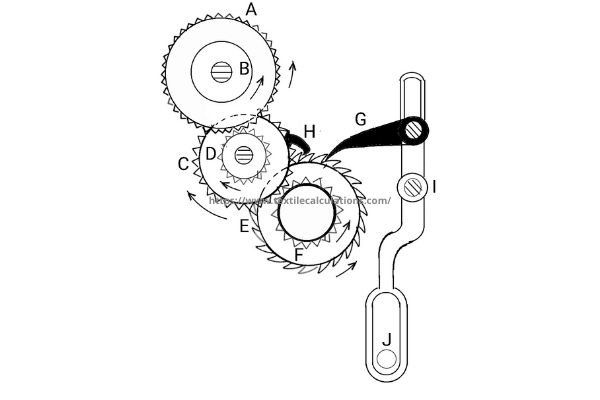

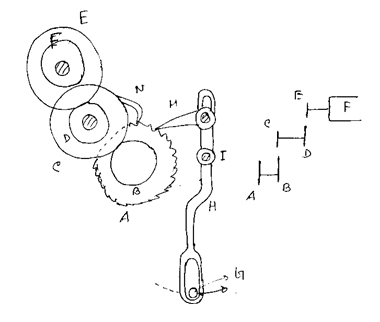

Where,

A = Rachet wheel = 50-60T

B = Change wheel = 1/4

C = Stud wheel = 100-120T

D = Stud pinion = 12-18T

E = Take up wheel = 60-100T

F = Take up roller = 15-16″ (circum)

G = Finger

H = Take up lever

M = Pushing pawl

N = Rotating catch

5-Wheel Take-up Mechanism Working Process:

- The beam wheel E is set screwed on the beam shaft and its teeth engaged those of stud pinion D which is connected with stud wheel C.

- The stud pinion and stud wheel work loosely upon a stud in a slotted bracket, the slot is concentric with the cloth beam F.

- This positive take-up motion is primarily imparted from the sley sword. The finger enters into the slot of the take-up lever H, which is fulcrum at I.

- A swinging motion is given to the sley sword and this will cause the paw M to drive the ratchet wheel A and set the train of wheels in motion.

- The rachet wheel is moved the distance of one tooth by the oscillating pawl for every pick.

- Thus motion is transferred to the cloth roller from the rachet wheel by means of five wheels.

Calculation of 5-Wheel Take-up Mechanism:

PPI: For one rev of one tooth of Rachet wheel (A) = 1 pick take-up

………………………………………………………….E C A

No of revolution of A for 1 rev of F = 1 x ….. x ….. x …..

………………………………………………………….D B F

……..75 120 50

= 1 x ….. x …… x ……

……..15 x 15

….2000

= ……….

……..x

Pick spacing:

………………………1…………x

Pick spacing = …….. = ……….

…………………….PPI……2000

………………………….B D F

Or Pick spacing = ….. x ….. x ……

………………………….C E A

……x……15…..15

= ……. x ….. x …..

….120….75….50

……..x

= ……….

….2000

Loom constant:

Loom constant is obtained by taking the no of teeth in change wheel = 1

………………………….E x C x A

Loom constant = ………………..

…………………………..D x 1 x F

…………………..Loom constant

Hence, PPI = ………..……………

……………………Change wheel

Contraction 1.5% is not added due to using coarse fabric, Jute, Blanket, Canvas fabric.

So, not adding of 1.5% contraction.