Weaving Calculations:

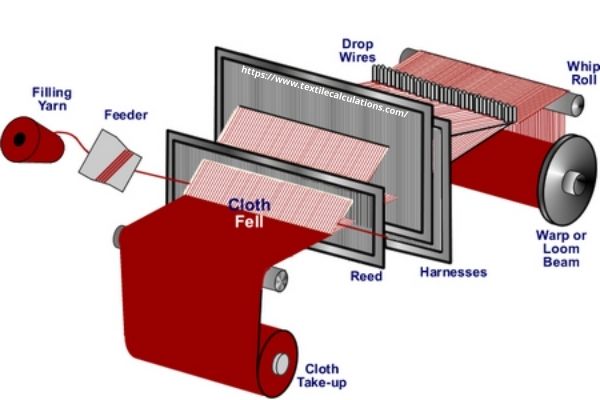

The process of producing fabric by interlacing warp and weft threads is known as weaving. The machine used for weaving is known as the weaving machine or loom. Weaving calculation is very important to produce the fabric. It is also a very critical task for the weaving master. Different formulas and calculation of weaving are given in this article.

Different Formulas of Weaving Calculation:

Reed Count: It is calculated in the stock port system.No. of dents in 2 inches is called Reed Count.

……………………………………….EPI

Reed count = ………………………………………….

……………………..1 + Weft crimp percentage

Reed Width:

…………………………………………100 + Weft crimp percentage

Reed Width = Cloth width X …………………………………………..

……………………………………………………………..100

Cloth Cover Factor:

…………………………………………EPI

1. Warp cover factor = ……………………..

…………………………………√Warp Count

…………………………………………PPI

2. Weft cover factor = ……………………..

…………………………………√Weft Count

……………………………………………………………..Wp.C.F. X Wt.C.F.

3. Cloth cover factor = Wp.C. – F Wt.C.F + ………………………….

……………………………………………………………………….28

Crimp % :

Crimp Percentage is defined as the mean difference between the straightened thread length and the distance between the ends of the thread while in cloth, expressed as a percentage.

…………………………Warp length – Cloth length

Warp crimp% = ………………………………………….. X 100

………………………………….Cloth length

………………………Weft length – Cloth length

Weft crimp% = ……………………………………… X 100

………………………………….Cloth length

Loom:

.…………………………………………Motor pully diameter

Loom Speed = Motor RPM X ……………………………….

…………………………………………..Loom pully diameter

……………………………………Actual Production

Loom Efficiency (%) = ………………………………. X 100

………………………………..Calculated Production

Fabric Specification:

……………………………………………..EPI X PPI

Fabric specification = ……………………………………. X Fabric width

……………………………….Warp count X weft count

Or

…………………………………Warp count X weft count

Fabric specification = ……………………………………….X Fabric width

……………………………………………EPI X PPI

Weight of yarn in a cloth:

The weight of cloth manufactured on looms depends upon the weight of yarns in the warp and weft: ends/ inch, picks/ inch, and the weight of size on the warp.

Therefore, Cloth weight = Weight of warp + Weight of weft + Weight of size (All in lbs.)

…………………………………………………Total No. of Ends X Tape Length in Yds.

Whereas Weight of warp in-lbs. = …………………………………………………………

……………………………………………………………840 X Warp Yarn Count

……………………………………..Length of Cloth (Yds) X Picks/inch in Cloth X Reed Width(inch)

Also Weight of weft in lbs.= …………………………………………………………………………………………

………………………………………………………………840 X Weft Yarn Count

Weaving Calculations:

Calculating linear yards of fabric produced on a weaving machine per hour of operation can be done using the following formula:

- Linear Yards/Hour = (picks per min. / picks per in.) x (60 min. per hr. / 36 in. per yd) x loom efficiency (%)

- Linear Meters/Hour = (picks per min / picks per centimeter) x (60 min. per hr. / 100 cm per meter) x loom efficiency (%)

- Square Yards/Hour = Linear Yards Per Hour x Fabric Width (Yds.)

- Square Meters/Hour = Linear Meters Per Hour x Fabric Width (Meters)

- Rate of Filling Insertion (Yards/Min) = Loom Speed (Picks/Min) x Loom Width (Yds.) x Loom Efficiency (%)

- Rate of Filling Insertion (Meters/Min) = Loom Speed (Picks/Min) x Loom Width (Meters) x Loom Efficiency (%)

Example of Weaving Calculations:

Example-1:

What is the linear yards of fabric produced on a machine running 650 picks per minute, inserting 58 picks per inch, and operating at a 92% efficiency?

Linear Yards/Hour = (picks per min. / picks per in.) x (60 min. per hr. / 36 in. per yd) x loom efficiency (%)

Linear Yards/Hour = (650picks per min. / 58picks per in.) x (60 min. per hr. / 36 in. per yd) x .92 loom efficiency

Answer: 17.2

Example-2:

What is the rate of filling insertion in a loom running 720 picks per minute with a width of 2.5 meters at 93% efficiency?

Rate of Filling Insertion (Meters/Min) = Loom Speed (Picks/Min) x Loom Width (Meters) x Loom Efficiency (%)

Rate of Filling Insertion (Meters/Min) = 720(Picks/Min) x 2.5 (Meters) x .93 Loom Efficiency

Answer: 1674 meters of filling inserted per minute

very helpful

very helpful

thanks for sharing this calculation very helpful