Ring Spinning Frame:

Ring Spinning Frame is the last stage in the process of conversion of fibers into yarn. The ring spinning machine was first invented in 1828 by the American Thorp. In 1830, another American scientist, Jenk, contributed to the traveler rotating on the ring. In this article, we will know about the calculation of draft and twist in ring spinning.

Calculation of Draft in Ring Spinning

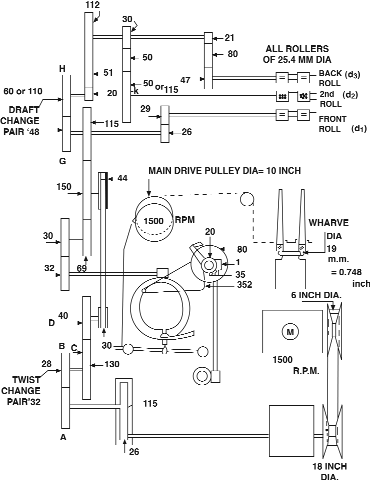

It is possible to achieve a very high range of draft and twist on modern long spinning frames. This is due to the provision of pairs of the draft and twists change gears in the mechanism as shown in the figure.

Calculation of Draft and Twist in Ring Spinning

All drafting rollers are of one-inch diameter.

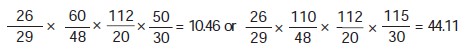

Draft between the middle roller and back roller:

![]()

Draft between the front roller and middle roller:

Total Draft between the front roller and back roller:

![]()

Thus, the range of draft varies from 14.05 to 25.75with the present draft gears. However, it can be further increased by the change of Gear H to 150 T in which case the range will increase from 14.05 to 35.115, and if Gear G is also changed to 24 the range will increase from 14.05 to 70.230.

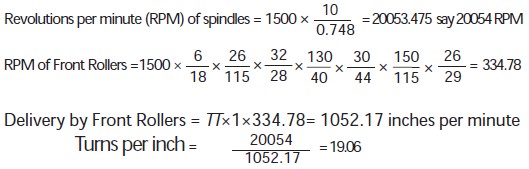

Calculation of Twist in Ring Spinning

By changing the speed of the main pulley and adjustments in the twist change and auxiliary twist change gears wide range of twists can be achieved.

Turns per inch of 19 to 20 are generally used by the spinners for spinning of 21 Ne warp yarn. In fact the spinners consider the fiber properties of cotton in deciding the twist multiplier for the particular count of yarn to be spun. The main focus is to use optimum twist level so that good quality yarn can be spun at a commercially competitive and industrially profitable output rate.