Experiment name:

Study on driving mechanism and production calculation of tappet loom.

Introduction:

A tappet having a rotary motion depresses a follower and a lever, known respectively as the anti-friction bowl and the treadle arrangement, by means of which the heald shaft is operated. A tappet is a cam having some dwell period which controls the up/down movement of heald shafts and the time of opening of the shed. Tappets are eccentric discs, which displace anti-friction bowls that are pressed against their active surfaces. The tappets can be of negative type or positive type.

Objectives:

- To know about the driving mechanism of tappet loom.

- To know about the production of tappet loom.

- To know about the different parts of the tappet loom.

- To write a report according to this experiment.

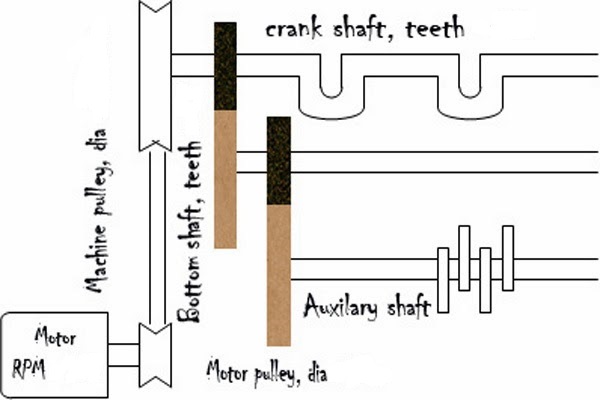

Different part of tappet loom:

- Motor

- Motor pulley.

- Machine pulley.

- Tappet

- Gear

- Crank Shaft

- Bottom shaft gear.

Specification:

- Motor RPM:1440

- Motor pulley dia:3.5inch

- Machine pulley dia:18inch

- Teeth of gear -1: 36

- Teeth of bottom shaft gear: 72

Construction of the driving mechanism:

- The machine pulley connected with motor by belt.

- Machine pulley is connected with crank shaft and crank shaft wheel.

- Crank shaft wheel connected with bottom shaft wheel. This rotates the bottom shaft.

Working Principle:

- When motor rotate the machine pulley also rotate because motor pulley connected with machine pulley by belt.

- Crank shaft wheel also rotate with machine pulley and crank shaft which transmit the motion to bottom shaft wheel.

Production of Tappet Loom:

Process-1:

………………………………………………………….Motor pulley dia Teeth of gear-1

RPM of Bottom shaft = Motor RPM x ———————————- x —————————–————

………………………………………………………….M/C pulley dia Teeth of bottom shaft gear

……………..3.5” 36

= 1440 x ——– x ——–

……………..18 72

= 140

PPM = RPM of Bottom shaft x 2

………………3.5” 36

= 1440 x ——– x ——– x 2

………………18 72

= 280

Process-2:

PPM = RPM of Crank shaft x 2

…………….3.5”

= 1440 x ———

…………….18

= 280

……………………PPM 280

Production = ———- = ———– inch/min

…………………….PPI 60

….280 x 60 x 8

= —————————— meter/shift

…..60 x 39.37

= 56.896114 meter/shift.

Conclusion:

By this experiment we came to know about gearing diagram and calculated the production of tappet loom.

You may also like: