Take up motion:

The process of withdrawing fabric from the weaving zone at a constant rate and then winding the woven cloth on the cloth roller with the continuous progress of weaving is called take-up. Take-up is to draw a fabric to the cloth roller regularly as it is woven. In this article, we will know about the calculation of the 7-wheel take-up mechanism.

7-wheel take up mechanism:

The 7-wheel take-up mechanism is a typical take-up mechanism which is generally used in cotton weaving.

Construction and working principle:

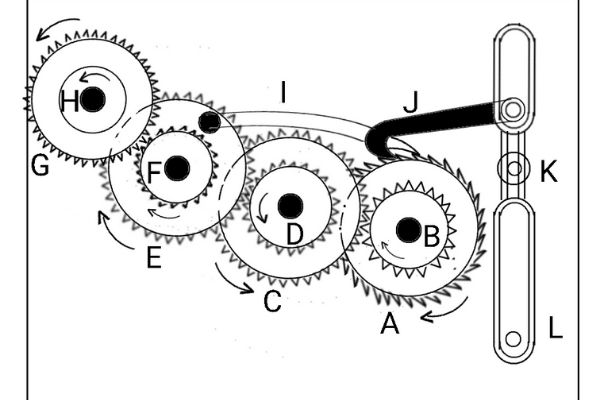

- A = Rachet wheel = 24 T

- B = Standard wheel = 36 T

- C = Change wheel = XT

- D = Swing pinion = 24 T

- E = Compound wheel = 89 T

- F = Compound pinion = 15 T

- G = Take up wheel = 90 T

- H = Take up roller = 15.05″ (circum)

- K = Retaining catch

- L = Pawl

- M = Finger

- N = Take up lever

Take-up lever N is centered at ‘I’ and has a pawl L pivoted upon it

A finger M is bolted and adjustable to a sley sword and passed through a slot in N

A swing motion is given to N and this will cause the pawl L to drive the Rachet wheel A and wet the train of wheels in motion. The amount of movement in L depends upon the position of M in the slot of N

The cloth is wound onto the cloth roller, as the sley falls back or as the sley moves forward.

Calculation:

PPI calculation:

For one revolution of one tooth of Rachel wheel (A)

= 1 pick take-up

…………………………………………………G x E x C

Then, No. of revolution of A = 1 x ………………..

………………………………………………….F x D x B

……….90…….89………X

= 1 x …… x ……… x …..….

……….15……..24……..36

…………………………………………….90 89 X

No. of picks for 1 rev. of H = 1 x ….. x …… x ……. x 4

…………………………………………….15 24 36

…………………………….90 89 X 24

Picks per inch = 1 x …… x …… x …… x ……….

…………………………….15 24 36 15.05

………90 89 60 24

= 1 x …… x …… x ……. x ……….. [C=60]

……….15 24 36 15.05

= 59.13

Pick spacing:

Pick spacing is the reciprocal of the pick density

…………………………….1

i.e. pick spacing = ……..

…………………………..PPI

………………………….B D F H

Pick spacing = 1 x …… x …… x …… x ……..

………………………….C E G A

…..36 x 24 x 15 x 15.05″

= ………………………………

……..60 x 89 x 15 x 24

= 0.0169 inch

Or pick spacing = X = 0.0169 inch

Loom Constant:

To find out the loom constant, the no of teeth in a change wheel is always = 1 i.e X = 1

…………………G x E x C x A

PPI = 1 x ………………………….

………………F x D x B x 15.05

…………..90 x 89 x X x 24

= 1 x ………………………………

………..15 x 24 x 36 x 15.05

…………………………………90 x 89 x 1 x 24

Loom constant = 1 x ………………………………

………………………………15 x 24 x 36 x 15.05

= 0.9836

Hence, PPI = Loom constant x change wheel

= 0.9856 x 60

= 59.136

In the loom, the fabric remains under tension. When it is out of the loom, it becomes relaxed. So in a relaxed state lengthwise contraction of the fabric increases the PPI of fabric and normally contraction is 1.5%

………………………..G E C . .A .. 100 + 1.5

Hence, PPI = 1 x ….. x …… x …… x ………… X ……………..

………………………..F D B .15.05 . 100

……….90 89 60 .,.24

= 1 x ……. x ….. x …… x ……… x 1.015

……….15 24 36 15.05

= 60.02

You may also like: Calculation of 5-Wheel Take up Mechanism