Introduction:

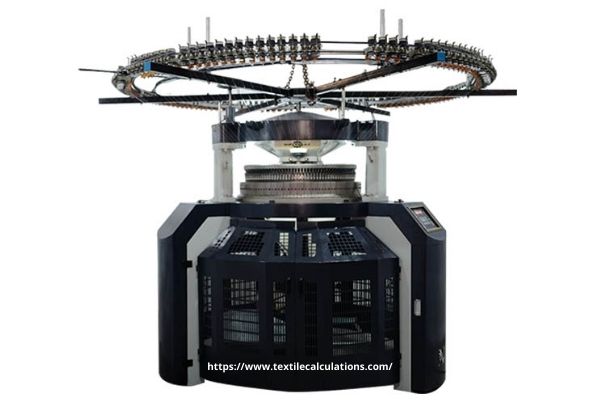

An interlock fabric comprising, in the simplest case, two-part courses. These part courses complement each other to make a full course, and therefore two systems or feeders are required for producing one course. Let’s find out the production of interlock circular knitting machines.

In the interlock circular knitting machine, there are 2 sets of needles namely cylinder & dial needle is placed at the right angle to each other. The machine operates by the main control unit. In the control unit, there is a small monitor where all running actions are seen on this monitor. After inserting all yarn in the required feeder, the machine is run in an inching motion to find out any fault.

Find Out the Production of Interlock Circular Knitting Machine

The following data were assumed for the interlock fabric production:

Example-1:

Values of circular knitting machine:

Machine diameter = 30”

Gauge E = 28

Number of feeders = 96

Machine speed = 31 rpm

Machine efficiency = 85%

Values of article:

Structure: plain interlock

Yarn: polyester dtex = 76/1

Course density = 17courses/cm.

Wales density = 14 wales/cm.

Fabric weight = 100 gm/m2

…………………………………………………………………………………..N X S X 60 X ŋ

Machine performance L in meter per hour = ………………………………………………………….

……………………………………………………………………feeders/course X courses/cm X 100

….31 X 96 X 60 X 0.85

= ……………………………..

………..2 X 17 X 100

= 44.64 m/hr

……………………………………………D X π X E

Fabric width, WB in meter = ……………………

…………………………………………..wpcm X 100

…30 X 3.14 X 28

= ……………………

…….14 X 100

= 1.88 m

………………………………………………………….L X WB X Weight in GSM

Machine performance in Kg per hour = ………………………………………….

…………………………………………………………………………1000

…44.64 X 1.88 X 10

= …………………………

…………1000

= 8.39 Kg/hr (ANS)

Example-2:

Values of circular knitting machine:

Machine diameter = 30”

Gauge E = 42

Number of feeders = 108

Machine speed = 31 rpm

Machine efficiency = 87%

Values of the article:

Structure: plain interlock

Yarn: polyester filament yarn dtex 50 of 88/1

Course density = 19 courses/cm.

Wales density = 23wales/cm.

Fabric weight = 100gm/m2

………………………………………………………………………………..N X S X 60 X ŋ

Machine performance L in meter per hour = ………………………………………………………

………………………………………………………………….feeders/course X courses/cm X 100

…..31 X 108 X 60 X 0.87

= …………………………………

……….2 x 19 x 10

= 45.99m/hr

……………………………………………..D X π X E

Fabric width, WB in meter = ………………………

…………………………………………….wpcm X 100

….30 X 3.14 X 4

= ……………………..

……….23 x 100

= 1.72 m

…………………………………………………………L X WB X Weight in GSM

Machine performance in Kg per hour = …………………………………………

………………………………………………………………………..1000

….44.99 X 1.72 X 100

= ……………………………

…………..1000

= 7.91Kg/hr. (ANS)